Are you having problems with your Walther PPQ? Below mentioned are all the malfunctions a Walther PPQ can have. Also, its causes and corrective measures.

Walther PPQ Problems and their Solutions

1. Failure to Feed

Your Walther PPQ might fail to feed. Failure to feed means that the cartridge is stuck moving from the magazine into the barrel when you pull the trigger. Below mentioned are all the probable causes of failure to feed and their solutions:

Causes and Corrective Measures

Magazine not seated properly: One possible reason for failure to feed is that the magazine is not seated correctly into the frame. It is a common problem, especially with new shooters, because they treat their weapons gently and don’t put enough force to seat the magazine into the gun. So, to avoid this problem, check the magazine and magazine release for proper engagement.

Wrong magazine: Having a wrong magazine can also cause failure to feed. Therefore, make sure you have a suitable magazine for your Walther PPQ.

Bent magazine feed lips: Another probable cause for the failure to feed on your PPQ is when you drop your gun on concrete or anything solid like that, the magazine feed lips bent. You have to replace the entire magazine to fix this problem because once the feed lips on a steel magazine bend, they don’t bend back the same way.

Dirty cambers or feed ramp: This problem can also occur when the chamber, the feed ramp, or both are dirty. The simple fix to this problem is to clean the barrel, the chamber, and the pistol.

Damaged feed ramp: A damaged feed ramp can also cause failure to feed. The simple fix is to replace the feed ramp.

Wrong or defective ammunition: One cause of failure to feed is that either your ammunition is defective or you are using the wrong one. Replacing the ammunition is the fix to this problem.

Weak recoil spring: Feeding issues can also occur if the recoil spring of your gun is weak. The corrective measure for this issue is replacing the guide rod assembly.

2. Failure to Return to Battery

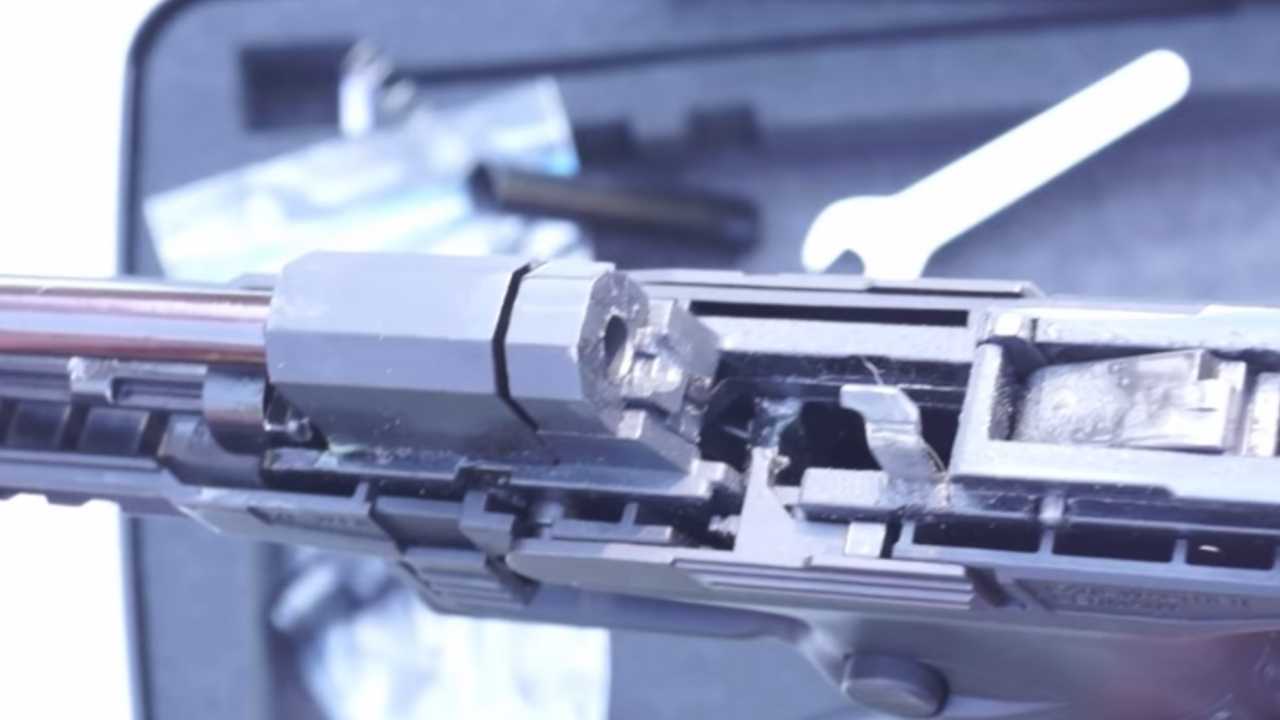

In this case, the slide fails to go forward to the place where the barrel locks up, and the disconnector allows the gun to fire. Why this happens is mentioned below.

Causes and Corrective Measures

Dirty chamber mouth: If the mouth of the chamber is dirty, it can cause the failure to return to the battery. The straightforward fix to this is to clean your chamber.

Weak recoil spring: You can also have this issue if your gun has a weak recoil spring. Replace the recoil spring assembly to fix this issue.

Ammunition failure: Failure of ammo is yet another cause for this problem. Replace the ammunition for fixing this issue.

The pistol is too heavily lubricated: When your pistol is too heavily lubricated, it can cause failure to return to battery. Generally, too heavily lubricated means that you have used a lube that was good in warm weather, but now, the lube gums up the gun in cold weather. The corrective measure to this problem is to strip the pistol and clean it. After that, lubricate it for the given environment.

Locking block damage: One relatively uncommon cause of this issue is locking block damage. The barrel and the slide are not correctly aligning while going back to the battery. So, the lugs on the barrel will not correctly align inside the locking block. Replace the locking block to fix it.

Dirty breechface or rails: When there is a lot of carbon build-up on the breechface, it causes this issue. So, make sure to clean the carbon build-up.

3. Failure to Fire

Below are the probable causes of failure to fire and their suitable solutions.

Causes and Corrective Measures

Dirty pistol: If your pistol is not properly cleaned and maintained, it can fail to fire. Clean and lubricate your PPQ to avoid this problem.

Dirt or obstruction in striker channel: If there is dirt or any other obstruction in the striker channel of your PPQ, it will fail to fire. To fix this issue, take the striker out completely, clean the striker channel, and then lube it.

Defective fire control assembly: If your gun’s fire control assembly is defective, it will fail to fire. The solution to this is that you replace it.

Broken striker after dry fire practice: If you do dry fire practice without snap caps, then your striker will break. With most modern service pistols, you can do a moderate amount of dry fire without snap caps. However, if you dry fire with your pistol excessively, you will break either the striker, the firing pin, or the striker spring. So, if you dryfire a lot, you have to have snap caps or dummy rounds to take that impact from the firing pin. But if your PPQ striker is broken already, you need to replace it.

Defective trigger spring or sear housing assembly: One reason for this malfunction is a defective trigger spring or rear housing assembly. If any of the two is defective, replace it.

Defective trigger assembly: This problem also occurs when the trigger assembly of your PPQ is defective. When someone has disassembled the gun and accidentally bent the trigger bar, a bent trigger bar does not interact with the striker’s safety. Also, once it is bent, you can not straighten it back. Hence, the only fix is to replace it.

Missing trigger bar guide: One more reason for this problem is that the trigger bar guide is missing. Sometimes, this can happen when you take the sear housing assembly out of the pistol frame, and the trigger bar guide will come apart from the sear housing. So, you want to make sure that you reinstall that properly when you put the sear housing back. If the problem is already there, install a new trigger bar guide to fix this issue.

The slide is not in the battery: One probable cause of this malfunction is that the slide is not in the battery. Most of the time, this happens because of defective ammo. However, another reason is if somebody rides a slide forward while chambering the first round and doesn’t apply enough force required to let the slide go. So, make sure to use enough force.

Dead round: When the round doesn’t fire on ejecting out, and you see a good dent on the primer, the chances are that the round is dead. The solution is to replace the ammunition.

Dead trigger: One reason for failure to fire is the dead trigger. When the slide is in a particular position and you press the trigger, it will prevent the striker from cocking. It happens because the slide and barrel move into the battery. If, in that position, you reset the trigger, it results in the dead trigger.

Also Read: Best Sights for Walther PPQ M2

4. Failure to Extract

Another malfunction you might face with your PPQ pistol is the failure to extract. Mentioned below are its causes and solutions.

Causes and Corrective Measures

Broken extractor: This issue is pretty common with a PPQ. The edge on the extractor claw may become rounded. If this problem occurs once in a blue moon, it’s because of the ammo, but it’s a broken extractor if it happens frequently. The solution is to replace the extractor.

Dirty chamber: Another probable cause for this malfunction is that the chamber is dirty. To solve this issue, clean the chamber.

Limp wristing: The solution is to have a proper grip on the gun, ensuring that your hand is up high on the beavertail. You have to make sure that you have a firm platform for the gun to operate against.

Squib load: The round will get caught in the barrel when the squib load happens. So, it won’t have the full force to pull the extractor back. To fix this issue, inspect the barrel and make sure it is clear. If there is a bullet inside of it, then disassemble the pistol to clear it.

5. Failure to Eject

Failure to eject is another problem you might face with your Walther PPQ pistol. The following are its causes and their solutions.

Causes and Corrective Measures

Dirty Pistol: One reason for this issue is that your pistol is dirty. Fix this issue by cleaning and lubricating your pistol.

Broken extractor: This problem also happens if your pistol has a damaged extractor. The solution is to replace it.

Underpowered ammunition: The cartridge does not reach back to the ejector when the ammunition is underpowered. Replace the ammunition to fix this issue.

Squib load: You need to clear your barrel to get rid of squib load. Replace the barrel if it is deformed.

Shooter-induced limp wristing: This problem can also occur due to limp wristing. To prevent this issue, get a firm platform.

Dirty pistol: Yet another reason for this malfunction is a dirty pistol. Clean and lubricate your gun to solve the issue.

6. Failure to Stay Open

Failure to stay open is the failure for the slide to lock to the rear on the empty magazine. Below are the causes of this problem and their solutions.

Causes and Corrective Measures

Underpowered ammunition: An underpowered ammunition can also cause this problem. The solution is to replace ammunition and use something more powered up.

Deformed parts: One cause is that the magazine or pistol is broken, the slide stop lever is broken, or the magazine tube is deformed. A notch will engage the slide stop when you have an empty magazine, and the last round comes out. If that notch is deformed or taken off, it will not engage it. The other is that the actual notch on the slide stop goes up into the slide. That is an induction hardened piece, but it could break off eventually. So, you are going to make sure you replace that. If the magazine tube is bent or deformed, the follower may not come. Try a spare magazine, repair or replace it.

Improper hand placement: Improper hand placement is the most common cause of this malfunction. This problem occurs when the shooters interfere with the slide stop lever with their firing hand thumb. To prevent this issue, keep fingers off the slide stop lever.

7. Slide Stop Early

The problem of slide stop early means that slide stop is bumping up early when the magazine still has ammunition in it, but now it’s prematurely locking slide over. Why this happens is mentioned below.

Causes and Corrective Measures

Broken slide stop spring: If the slide stop spring is broken, then your slide stop floats, and then under recoil, it would just pop up and catch that slide. When you up the slide stop and it just flops, and there is no spring tension keeping it down, then you know that the spring is broken. Its solution is that you replace the slide stop spring.

Improper hand placement: Again, this is a common cause when the individual bumps the slide stop up with their thumb while firing and locks the slide to the rear prematurely. Evaluate and correct it.

Overpowered ammunition: The overpowered ammo will blow the slide back so hard that it will engage the slide stop. The fix to this problem is to replace the ammunition.

8. Unintentional Magazine Release

An unintentional magazine release means that the magazine drops unintentionally. Below mentioned are the causes and solutions of this problem.

Causes and Corrective Measures

Magazine not properly seated: This problem occurs when you don’t seat the magazine in the frame properly. The solution is to check magazine and magazine release for proper engagement. Also, replace if necessary.

Weak magazine release spring: This means that as you are shooting, the spring is so weak that your grip interferes with the button and depresses it. The solution is to install a new magazine release spring and bumper.

Missing bumper: This problem also occurs when the bumper is missing. The solution is to install a new magazine release spring and bumper.

The magazine release is broken: This problem also occurs when the magazine release is broken. Again, the solution is to replace the whole assembly.

9. Drifting Rear Sight

Below is the probable cause of this problem and its solution.

Causes and Corrective Measures

The sleeve underneath the rear sight is missing: A specific sight uses an expanded roll pin to hold it in place. If that sleeve is not there, then that sight will float freely. The fix is to replace the rear sight.

10. Front Sight Comes Off

Below mentioned is the cause of this malfunction and its fix.

Causes and Corrective Measures

Loose front sight screw: This problem occurs when the front sight screw is loose. The solution to this problem is to replace the front sight. And to prevent this problem, ensure that you use the proper lock tight on your front sight and the proper torque.

Also Read: Best Light for Walther PPQ M2

EndNote

My personal opinion is that PPQ pistols are reliable. But if you face any of the above malfunctions, take these measures to fix them.

FAQs

Is the Walther PPQ reliable?

The Walther PPQ gives accuracy. It has an incredible trigger and excellent ergonomics. It works with easily visible sights that give faster target acquisition. Also, there are many options for aftermarket sights for a Walther PPQ.

What is a PPQ 45 used for?

PPQ 45 is an efficient gun with good ergonomics. You can also use it as a home defense gun and range toy.

Is PPQ navy a good gun?

PPQ navy has excellent ergonomics for self-defense. In addition, the slide’s design is made to drain the water from the striker channel, making it practical for Maritime operations.